|

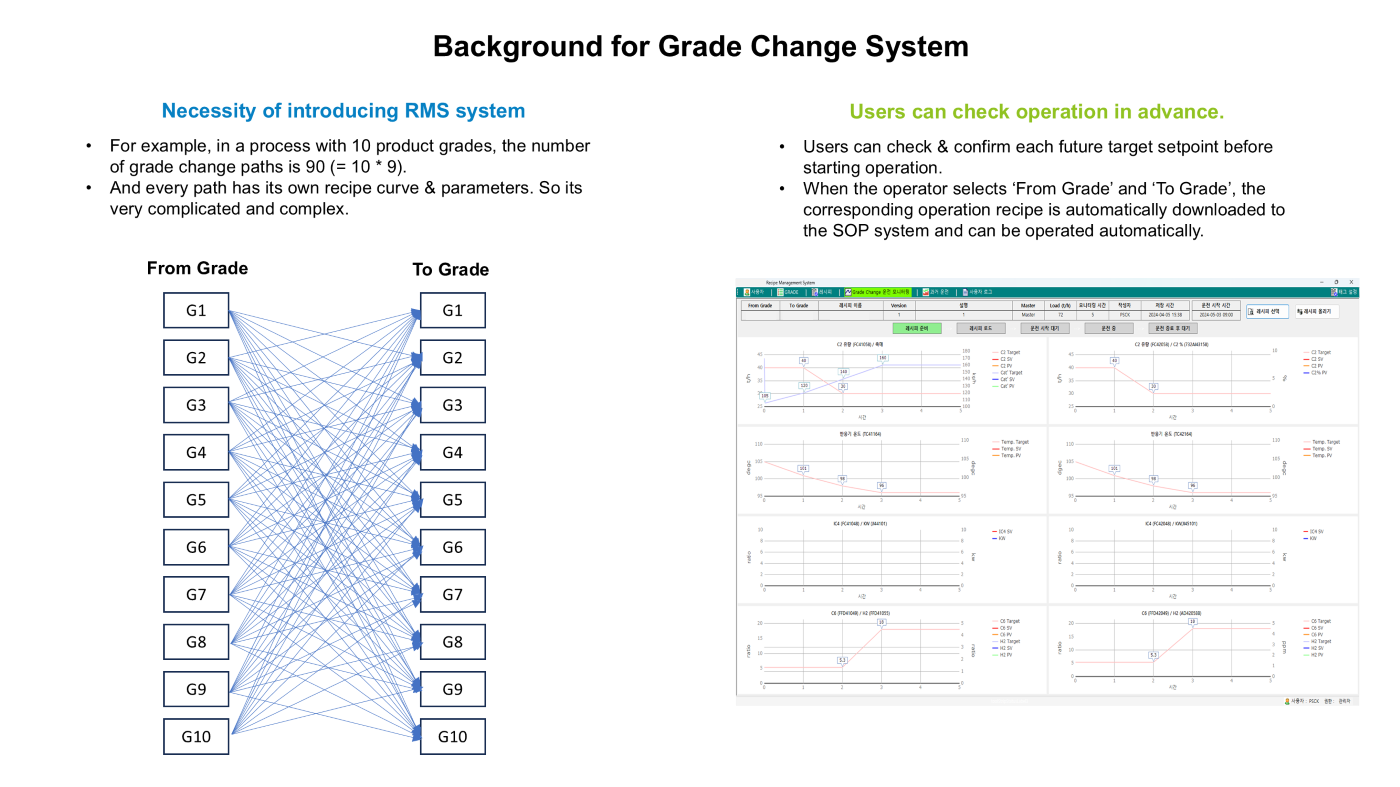

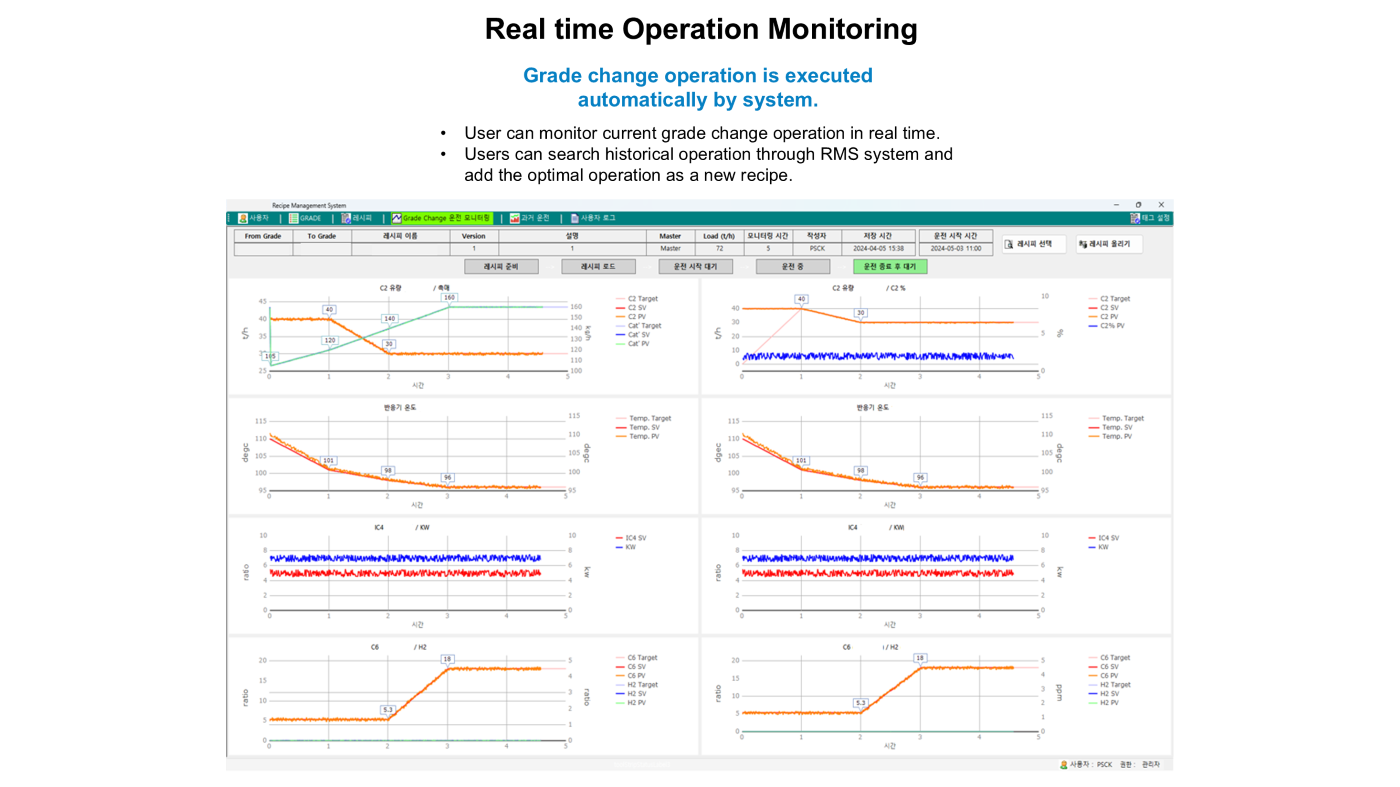

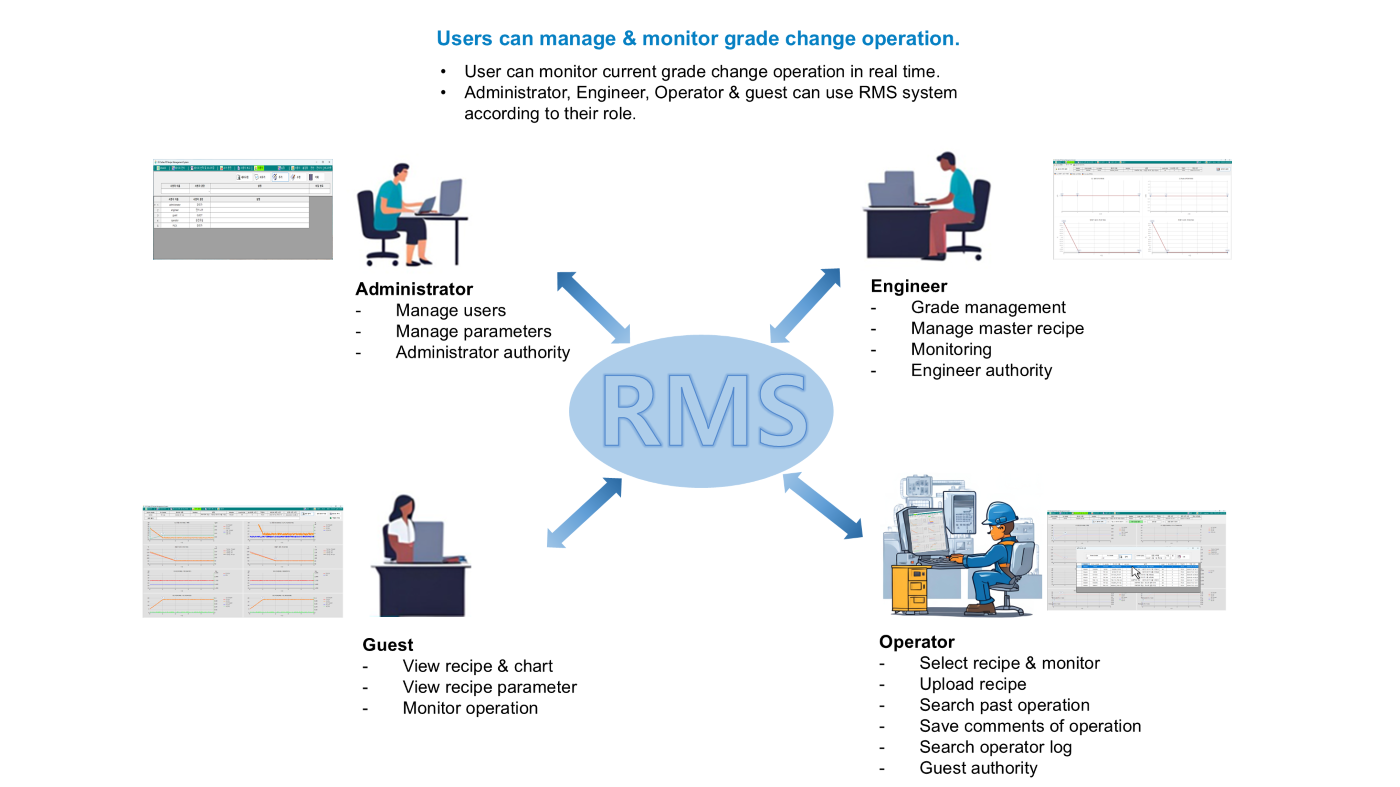

1. Background for Grade Change System 1) Necessity of introducing RMS system For example, in a process with 10 product grades, the number of grade change paths is 90 (= 10 * 9). And every path has its own recipe curve & parameters. So its very complicated and complex. 2) Users can check operation in advance. Users can check & confirm each future target setpoint before starting operation. When the operator selects ‘From Grade’ and ‘To Grade’, the corresponding operation recipe is automatically downloaded to the SOP system and can be operated automatically. 2. Real time Operation Monitoring Grade change operation is executed automatically by system. User can monitor current grade change operation in real time. Users can search historical operation through RMS system and add the optimal operation as a new recipe. 3. Real time Operation Monitoring Users can manage & monitor grade change operation. User can monitor current grade change operation in real time. Administrator, Engineer, Operator & guest can use RMS system according to their role. |